Hiroyuki Hirano introduced 5S Methodology to improve the production systems through critical steps. This Methodology is famous for revolutionizing the production system of the renowned carmaker Toyota, Japan.

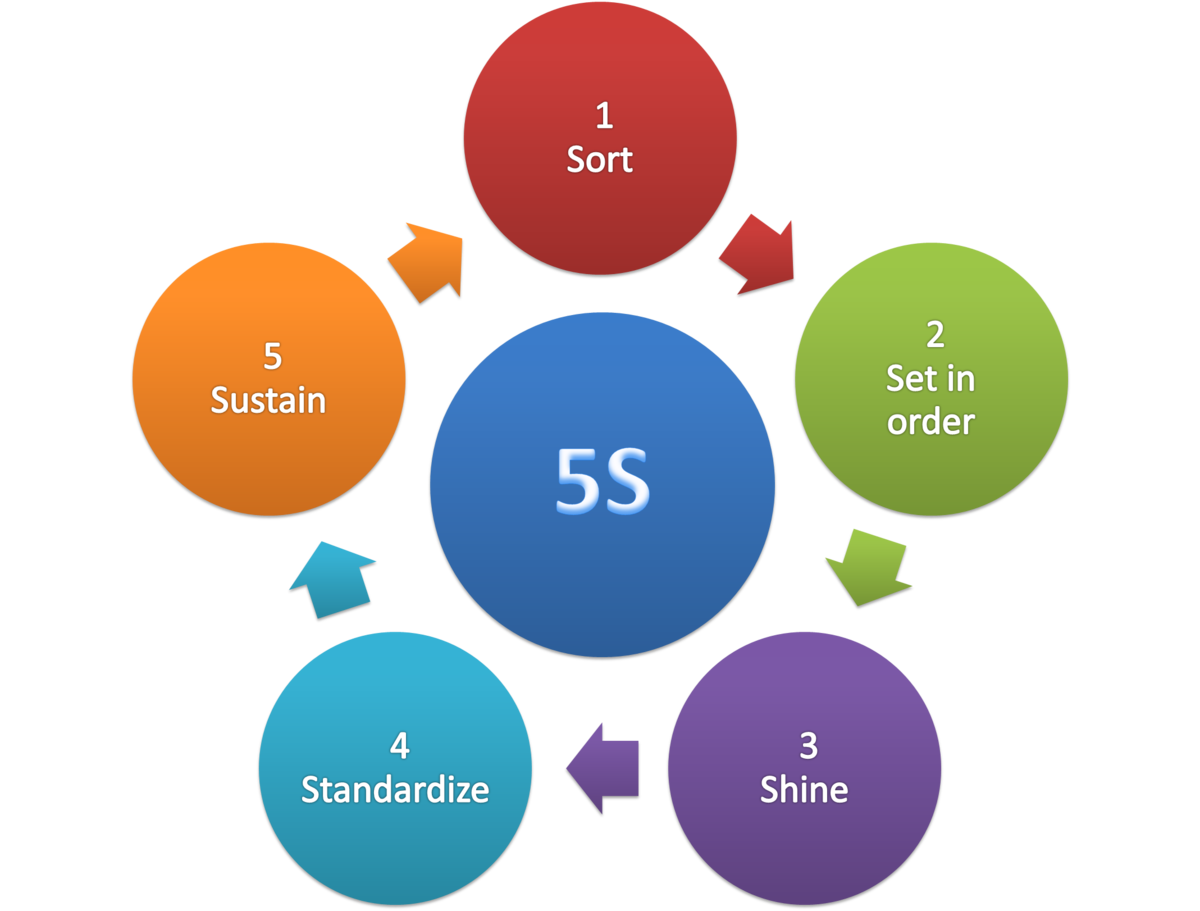

The 5S is one of the prestigious members of the Lean Management tool kit as it helps employees to remove the waste under its Lean Manufacturing system. It revolutionizes businesses' operations by removing waste and helping people with 5S Safety protocols. 5S is an acronym for Japanese words:

-

Seiri = Sort

-

Seiton = Set in Order

-

Seiso = Shine

-

Seiketsu = Standardize

-

Shitsuke = Sustain

Before digging deeper into the meaning of these terms, let's focus on the benefits of 5S to your organization:

Different stages of 5S involve sorting unnecessary items in the workspace and removing them to optimize the workplace.

One of the 5S stages, Shine, means cleaning focuses on a clean working system to provide a healthy workplace to the employees. Under this step, participants work hard to remove all the dirt and unnecessary item from the workplace to endure the excellent health and safety of employees.

During the first stage of 5S, sorting and red labeling are done to identify the items that are damaged or not valuable from the current project's point of view.

The 5S method under its sustainability phase involves active participation from all team members. It gives workers a sense of responsibility and ownership.

The 5S complies with International Health and safety standards. The Occupational Health and Safety Management System or ISO 45001:2018 is an internationally=acclaimed protocol that helps organizations to set up a process and take initiatives to reduce injury-related risks at the workspace. This ISO standard is followed in most industries, including healthcare, manufacturing, and warehousing.

Understanding 5S in the workplace

Seiri = Sort

The Japanese word 'Seiri,' meaning Sort, is the first and the most crucial stage of the 5S Methodology. This stage helps to remove all the unwanted tools, machinery, equipment, and other items that are not required in the workspace. The sorting step allows you to keep your work area clean.

Most professionals sort items and put a red label on them. These red labels give information about the status of that item. They store all the red-labeled items in a storage area for future use. The things used in the workplace should be kept near the workspace, while those not required can be stored in the storage area.

Seiton = Set in Order

The term' Seiton' means Set in Order stage, as the name suggests, means setting items where they can be easily accessed. You need to assess different spaces and use methods to store items in a proper place. All items should be kept at safe locations.

To set everything in order, use labels and a color-coded system to identify different items. This will help you to access them efficiently. The main advantage of putting everything in place is to free up extra space. Items containing Hazardous material should be stored at safe locations.

Seiso = Shine

Term 'Seiso', meaning Shine stage, comes after you have removed all the unnecessary stuff and set everything in order. Under Shinning stage comes the cleaning of tools, machinery, equipment, and workspace items every day. This step is essential to follow the 5S Methodology in the long run.

If you find it hard to clean tools and equipment daily, you can create a checklist and mark done items that you cleaned today and maybe clean tomorrow. This will save you from unnecessary hard work. Assign this task to everybody. Make sure every employer is responsible for cleaning his or her workspace at all times.

Seiketsu = Standardize

5S method stage 4 represents the Japanese term 'Seiketsu, ' meaning Standardize. This step is important to ensure all the previous steps by Seiri, Seiton, and Seiso are implemented. This stage helps to get the benefits of the first three stages of the 5S method. The new practices will never become the new normal for the company.

To implement this stage, schedule a meeting with each division or department in your company. This meeting should involve all the workers and their managers. Present the new standards and convey information via messages, emails, etc. Implementing this stage will benefit you and your enterprise in the long run.

Shitsuke = Sustain

The last stage of the 5S method, the term 'Shitsuke,' meaning Sustain, is the last but not the least stage that wants commitment from all members of the organization. This commitment is made to maintain and follow the standards set in Stage 4. To implement this stage, employers need to develop a formal system involving the training of workers. This training must incorporate information about new changes ensuring health and safety. Teaching self-discipline to workers will give positive changes from Sort, set in order, and " shine" the workplace.

This 5S Methodology helps to remove obstacles and improve productivity at work.

文章定位: